Have you ever wondered what gives an epoxy floor coating its strength and durability? It’s all thanks to the chemical makeup of the epoxy resin. Epoxy flooring is used in many industrial and commercial settings because it is able to withstand heavy foot traffic and equipment traffic. It is also resistant to many chemicals, making it ideal for use in areas where there might be spillage.

Epoxy coating has a very low porosity, which means that it is also resistant to staining. There are many different types of epoxy formulations, but they all contain a base resin and a curing agent. In this article, we’ll take a closer look at the ingredients in an epoxy floor coating and how they work together to create a strong and durable finish.

Table of Contents

What Exactly is Epoxy?

Epoxy is a type of polymer that is made up of long chains of molecules. These chains are very strong and resistant to breakage. When the epoxy is used as a floor coating, it forms a strong bond with the surface it is applied to. This bond is what gives epoxy its strength and durability. Epoxy coatings are a popular choice for floors in industrial and commercial settings because they can withstand a lot of wear and tear.

Epoxy flooring is made up of two main ingredients: a base resin and a curing agent. The base resin is what gives the epoxy its strength and durability. The curing agent is what allows the epoxy to harden into a strong

What Can be Added to Epoxy?

There are many different formulations of epoxy, and each one is designed for a specific purpose. For example, some epoxies are designed to resist high temperatures, while others are designed to be more flexible. There are also epoxies that contain additives that give the finished product a certain color or finish. Some of the most common additives include:

Fillers: Fillers are added to epoxy to give it a certain texture or appearance. For example, sand can be added to epoxy to create a non-slip surface. This is often done in commercial kitchens or other areas where there is a lot of foot traffic.

Color Pigments: Color pigments are added to epoxy to create the desired color. This is often done to match the décor of a room or to create a certain ambiance. By adding different color pigments, you can create any color you want and give your epoxy flooring a unique look.

Non-skid Additives: Non-skid additives are added to epoxy to create a non-slip surface. This is often done in areas where there is a lot of foot traffic, such as commercial kitchens or industrial factories. In some cases, non-skid additives are added to epoxy to create a decorative effect.

How Does Epoxy Work?

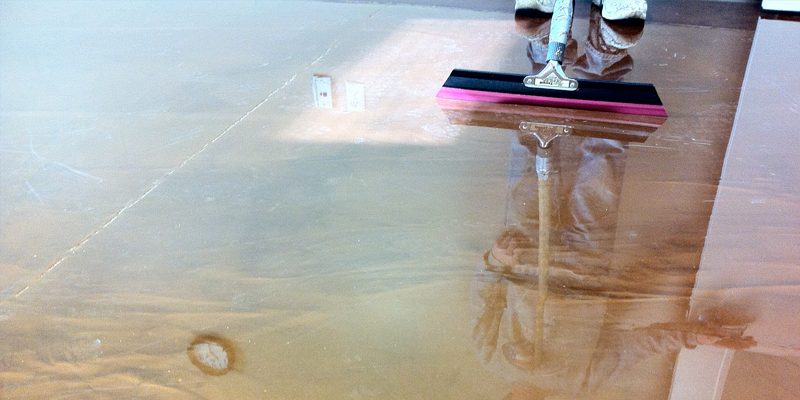

Epoxy flooring works by bonding with the surface it is applied to. This bond is created when the base resin and curing agent react with each other. The reaction between the two ingredients causes the epoxy to harden into a strong and durable finish. The look of epoxy flooring can be customized by adding different additives to the base resin and curing agent. For example, you can add color pigments to create the desired color, or you can add fillers to create a certain texture.

Once epoxy cures, it forms a very strong bond with the surface it is applied to. This bond gives epoxy its strength and durability. Epoxy flooring is a popular choice for many industrial and commercial settings because it can withstand a lot of wear and tear.

What are the Advantages of Epoxy Flooring?

Epoxy flooring has many advantages over other types of flooring. For example, epoxy is very strong and durable, making it ideal for use in high-traffic areas. Epoxy is also resistant to many chemicals, making it ideal for use in areas where there might be spillage. Epoxy coating has a very low porosity, which means that it is very resistant to staining. Epoxy flooring is also easy to clean and maintain. When properly cared for, an epoxy floor can last for many years.

What are the Disadvantages of Epoxy Flooring?

Epoxy flooring has a few disadvantages. For example, epoxy flooring can be very slippery when wet. This can be a safety hazard in areas where there is a lot of foot traffic. Epoxy flooring is also susceptible to UV damage, so it should not be used in outdoor applications. In some cases, epoxy flooring can be difficult to repair if it becomes damaged.

Epoxy flooring is a popular choice for many industrial and commercial settings because of its strength and durability. Epoxy flooring is one of the most popular types of flooring for use in high-traffic areas. Epoxy flooring is also easy to clean and maintain, making it a good choice for many different applications. If you are considering using epoxy flooring in your home or business, it is important to weigh the pros and cons to decide if it is the right choice for you.